Introduction: This page gives an overview of the company with details of its more recent activities. See also this 1938 article, published in the house magazine at the time, which recounts more of the early history of Simplex. |

| —Bill Burns |

The Simplex Wire & Cable Company had its beginnings

in 1865 with the formation of a partnership between Charles A. Morss, who

had his own wire making firm in Boston, and Oliver Whyte, to manufacture

wire products. They made their first insulated wire in 1885 as an experiment.

Following a fire in 1888 the company moved to new premises in Cambridge,

Mass.

In 1890 Morss and Whyte took over the Simplex Electric

Company who had been acting as selling agents for them. They merged the

two firms in 1895 under the Simplex name. This company was to concentrate

on the manufacture of insulated wire and cable.

One of the first submarine cables the company made was a

five mile telephone cable, which was laid across the Straits of Mackinac

in Lake Michigan; another, one mile in length, was laid across

Boston Harbour. Both were laid in 1900.

Problems in obtaining gutta percha for insulation

forced the company to use rubber insulation, which only lasted for a few

years due to proteins in the rubber absorbing moisture. To get over this

Simplex used lead sheathing on some cables. But by 1926 they had developed a

protein free rubber which they used for power and telephone cables.

From a 1931 product advertisement |

The first submarine cable using the new product was

made in 1931 for the US Coast Guard and was laid by USCG CS Pequot from Miami to Key Biscayne and on to the Fowey

Rocks Lighthouse. The success of this cable led to many similar contracts.

During World War II they produced over 3000 miles of cable for the US

Army Signals Corps Alaskan Communication System as well as cable for harbour

and coastal defence work.

1943 Letterhead |

Bell Telephone Laboratories restarted their research

on telephone cables after the end of World War II and Simplex was invited

to join in on cable and repeater housing development. In 1948 Simplex

manufactured 20 nm of coaxial cable which with six repeaters was laid

by CS Lord Kelvin in the Bahamas. The first commercial system using

the new cable was laid between Key West and Havana in 1950 using twin

"go" and "return" cables. Twin cables were also used

on the Atlantic Missile Range System installed in 1953 by HMTS Monarch

(4); repeaters for this cable were installed on land.

On the 26th November 1953 the company opened a new

factory on the banks of the Piscataqua River at Newington, New Hampshire

solely for the manufacture of cables, both power and telephone.

Some other cables manufactured by the Company:

| 1952-4 |

Florida - Puerto Rico. For the USAF |

| 1955 |

TAT 1 350 nm shore end cable and

58 repeater repeater housings |

| 1956 |

Port Angeles - Ketchikan 1250 nm

of cable and 36 repeater housings |

| 1957 |

HAW 1 2380 nm of cable and 98 repeater

housings. |

| 1957 |

Cape Dyer - Thule 1450 nm of cable

and 30 repeater housings. For the USAF |

| 1959 |

TAT-2 600 nm of cable and 114 repeater

housings. |

| 1960 |

Florida - Puerto Rico 1200 nm of

cable and 38 repeater housings. |

| 1961 |

Cape Dyer - White Bay 2050 nm of

cable and 45 repeater housings. For the USAF |

| 1962 |

Creole Petroleum - Lake Maracaibo,

Venezuela 22 nm of 35 kV single phase power cable. |

| 1963 |

Puerto Rico - Viques Island 10 nm

of 35 kV 3 phase power cable. |

| 1964 |

Wet Wash A: Philippines - Vietnam 696 nm of cable. |

| 1966 |

Wet Wash C: Hawaii - Johnston Island 769 nm of

cable. |

| 1966 |

Gulf Coast Telephone Co 150 nm of

cable. |

| 1967 |

Vietnam coastal system 961 nm of

cable. For the USAF |

| 1967 |

Vietnam - Thailand 607 nm of cable.

For the USAF |

| 1967 |

Chugach Electric - Cook Inlet, Alaska

14 nm of 138 kV power cable. |

| 1968 |

Union Oil - Santa Barbara Channel,

California 66 nm of power and signal cable. |

| 1968 |

Bonneville Power - Puget Sound, Washington

69 nm of power cable. |

| 1971 |

Taiwan - Okinawa 363 nm of cable. |

| 1973. |

Mt. Dessert Island - Swans Island,

Maine 5¼ nm of power cable. |

| 1976. |

TAT 6 shore ends. |

| 1993 |

HAW 5 San Luis Obispo, California

- Keawaula, Hawaii. With AT&T SSI |

Many cables were also produced for United States defence

systems, including work for the United States Naval Electronic Systems

Command. In addition many submarine power cables have been manufactured

by the company.

1962 Postmark |

1968 Logo |

In 1974 the company was taken over by Tyco, and the Newington site is now part of the Subcom complex.

|

| Simplex Cable for TAT-1 - 1955 |

Site visitor Robert Falt sends a letter from Simplex about the company’s work on TAT-1, the first transatlantic telephone cable, opened for service in 1956. Robert’s grandfather worked for Simplex, and was presented with a paperweight containing a short section of the cable that the company had made for the project, together with the letter.

Simplex Wire & Cable Co.

1955 Transatlantic Telephone Cable Type A

|

SIMPLEX WIRE & CABLE

MANUFACTURERS

79 SIDNEY ST., CAMBRIDGE 39, MASS.

November 1, 1955

TRANSATLANTIC CABLE SAMPLES

As a result of the great interest expressed in our Company’s share in the Transatlantic Telephone Cable, we have made up a few samples in the form of paper weights.

These have been widely distributed in Newington, where nearly every individual employed there actually worked on the job. We are making a limited distribution of them in Cambridge, and it is with pleasure that I hand you one of them.

The first Transatlantic line, namely the cable for eastbound conversation, which was laid during the summer of 1955, was approximately 2000 miles in length. For this line, Simplex delivered 217 miles of Type A cable and 150 miles of Type D cable.

The Transatlantic line for westbound conversation will be laid next summer. It will contain no Simplex cable. However, our capacity for this type of cable has been kept fully occupied since the early fall of 1954 and is now completely scheduled to April 1, 1957.

We are now working on a double line of this same type of cable, which will be a deep water run from Seattle to Ketchikan, at the southern edge of Alaska, where it will be connected to a cable which we shipped out last December to the Signal Corps. The Signal Corps cable is a single line running up the inland waterway to Sitka, Alaska. Because it runs in the inland waterway, it will have land based repeaters, thus avoiding the necessity of a double line. The deep water run will include about 1600 miles of cable, and the inland run about 600 miles of cable.

After completion of this Alaska job, we will start production on our share of the San Francisco - Honolulu cable, for which we expect to make in excess of 2000 miles. This line is scheduled to open for service on Christmas, 1957. It will require the combined production capacity of Simplex and the British to meet the dates.

|

| |

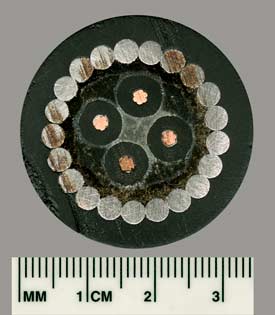

| Simplex Cable Recovered in 2009 at Cape Cod, Massachusetts |

|

The cable shown to the left was recovered from the ocean at Barrier Beach in Chatham, Massachusetts, by Richard Sandstrom.

Marked "Simplex" and "Bunass", the cable is 1⅜" diameter with a black polyethylene outer coating, 21 steel armoring wires, and four seven-strand copper conductors.

Possibly used for telephone communication, it’s believed that the cable ran from a lifesaving station named Old Harbor Station, back North up the peninsula and built in 1898, to a lifesaving station in the town of Orleans. The date is unknown, but the design of the cable suggests the end of the 1950s or later.

If any site visitor has further information on this connection, please email me. |

Recovering cable, October 2009 |

|

| |

Sample Simplex Cable Specification

SIMPLEX .128"/.460" TELEPHONE CABLE

Simplex telephone cable, 1968 |

The cable is intended for use as a communications circuit for underseas operation. It is made up of the following components.

Central Conductor: One 0.128"-diameter solid, uncoated, soft copper wire of high quality and purity, not tinned.

Insulation: High-quality and -purity polyethylene extruded to a diameter of 0.460".

Return Circuit: Six 0.015"-thick x 0.238"-wide uncoated, soft copper tapes of high quality and purity, not tinned, spirally applied. The diameter over the tapes is approximately 0.49".

Shielding: One 1¼"-wide x 0.004"-thick, uncoated, soft copper tape of high quality and purity. Diameter over the tape is approximately 0.50".

Binder Tape: One 1¼"-wide x 0.015"-thick coated cotton tape. The diameter over the tape is approximately 0.53".

Armor Bedding: One serve of 60-lb. treated jute roving. The diameter over the jute is approximately 0.66".

Armor Wires for Deep-Sea Cable: Twenty-four 0.086"-diameter galvanized extra-high-strength-steel wires, each coated with a tar preservative. The diameter over the wires is approximately 0.80".

Outer Covering: Two serves of treated 17/3 plied jute yarn with a flooding of tar preservative compound under, between and over each serve. The diameter over the finished cable is approximately 1.04". For shore ends and unusual bottom conditions, special armoring may be required. Consult factory for specific recommendations.

| CALCULATED CABLE DATA |

| Over-all Diameter |

1.04" |

| Weight in Air |

5,320 lbs/NM |

| Weight in Sea Water |

3,490 lbs/NM |

| Minimum Breaking Strength |

30,000 lbs. |

Cable Modulus

(Breaking Strength/1-NM Weight in Sea Water) |

8.6 NM |

| Specific Gravity |

3.06 |

|

|