The album is titled on the cover:

Cable & Repeater Divisions

Submarine Cables Limited

And on the inside title page:

Submerged Repeaters and Co-Axial

Cable for Trans-Oceanic Telephone Service

Views of Manufacturing

Operations at

Submarine Cables Limited

Ocean Works, Erith, Kent

and

Greenwich, London, S.E. 10 |

1. Manufacture of electrical components under clean and rigorously controlled conditions. |

2. View of assembly area for submerged repeaters. |

3. Inspection of an end casting for a repeater internal unit. |

4. Inspection of a repeater amplifier chassis. |

5. Inspection of a repeater casing. |

6. Inspection of plates for silvered mica capacitors. |

7. Assembly of silvered mica capacitors. |

8. Coil winding. |

9. General view of assembly and testing of repeater units. |

10. Mounting of polystyrene capacitors. |

11. Assembly operations on a supervisory unit. |

12. An early stage of wiring on an amplifier. |

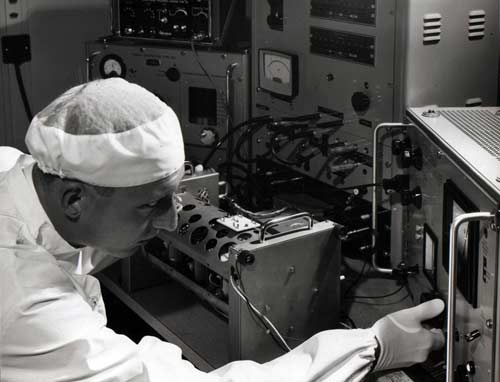

13. Transmission testing of a filter unit. |

14. Transmission testing of an amplifier unit. |

15. Assembling individual repeater units. |

16. Internal unit of a repeater before insertion and sealing into a brass tube. |

17. The repeater in its pressure resisting casing is sealed by high frequency brazing. |

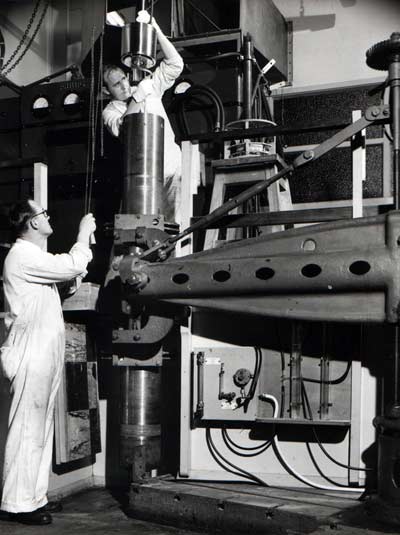

18. Pressure testing of housed repeaters at 5 tons per square inch. |

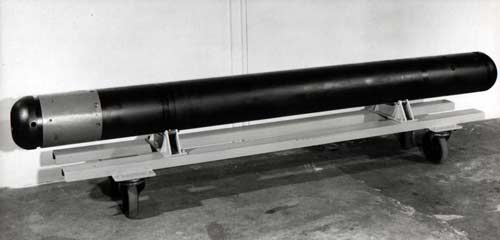

19. Completed repeater after housing. |

20. Equipment for the confidence testing of repeaters for a three month period. |

21. Confidence testing of repeaters at sea bottom temperatures. |

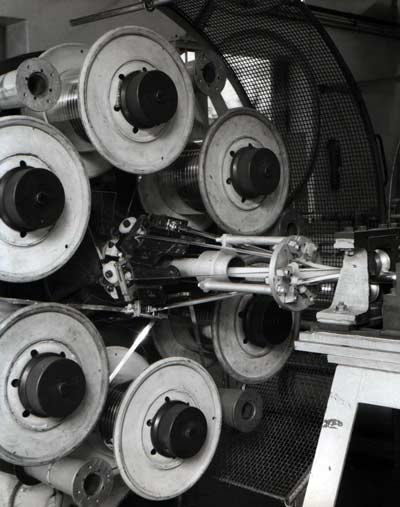

22. General view of two of the core extruders.

|

23. View of coiling down in containers accommodating 26 n.m. of core.

|

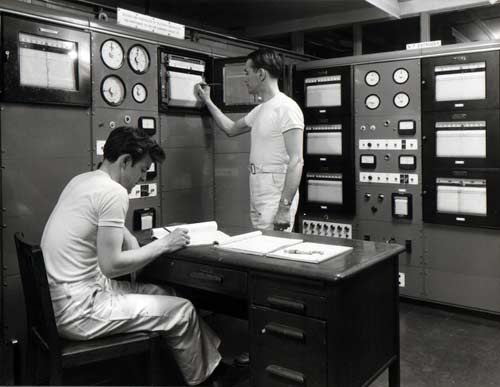

24. Part of core extrusion control room. |

25. Examined core coiled in tanks for electrical tests. |

26. Application of aluminium tapes to form outer conductor. |

27. View of an oversheathing extruder. |

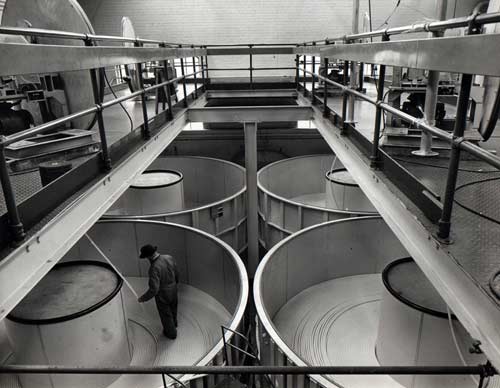

28. View of tanks each storing 200 n.m. of completed cable. |