Landline fiber optic communications cables first went into service in 1977, but, as with copper cables, ensuring reliable operation using optical fiber cables under water was a task of a higher magnitude. By the early 1980s optical fiber submarine cables were under development in Japan, Britain, France, and the USA, and a number had been successfully tested in shallow water.

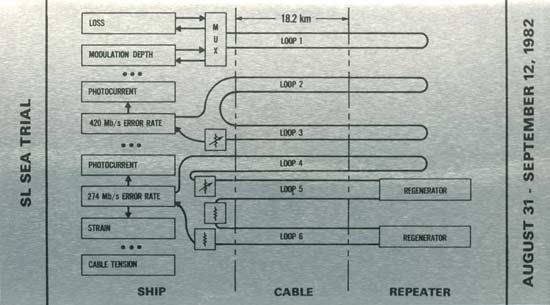

In the United States, Bell Laboratories and the Simplex Wire and Cable Company jointly researched fiber optic submarine cables, and in 1978 Bell Labs manufactured a prototype, the first ever made. Bell Labs also worked with Western Electric to develop an integrated-circuit-based optical submarine repeater. By late August 1982 a length of 18.25 km of lightweight fiber optic submarine cable, type SL, had been manufactured by Simplex, and the cable and a repeater with two 274 MB/s regenerators were ready for test.

A 1983 short film from the AT&T Tech Channel, “SL Lightwave Undersea Cable System,” showing the development and testing of the new technology, is unfortunately no longer on line as of 2023.

A deep-sea trial was conducted between 31 August and 12 September 1982 using CS Long Lines. The cable and repeater were laid in the North Atlantic about 500 miles from Bermuda in an ocean depth of 5,500 metres; the run also included a number of splices. Tests showed that transmission losses due to temperature, tension, and pressure changes were negligible, and the cable and splices survived the stresses of laying and picking up without any fiber breaks. This was significant in being the first-ever deep-sea trial of a fiber optic cable system.

In addition to the trial and measurements at sea, the Ocean Simulation Facility at the Holmdel Laboratory was used to model deep-sea laying and operating conditions.

[Undersea Lightwave Communications p.241].

In the ocean simulator, cable samples of 100m (~328 ft) length were used to check any degradation in the light transmission ability of the fibers under deep-sea conditions. Each test program took up to two weeks to complete, and it was found that the losses were minimal.

See below for further information on the Holmdel site.

Desk display commemorating the first-ever deep-sea trials

of a lightwave communications system in September 1982. |

The desk display shown above commemorates the 1982 sea trial, and includes a small section of the SL fiber optic cable, a map of the test location, and (on the reverse) connection details of the cable and equipment used in the tests.

SL Cable. |

Detail of core. The optical

fibers are the tiny black dots surrounding the

copper-clad

steel kingwire at the center

|

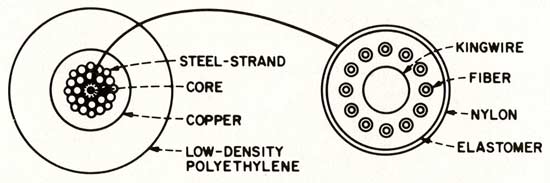

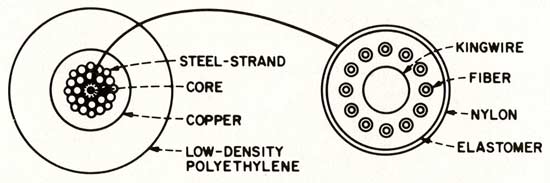

| The central core is 2.6mm in diameter and contains up to twelve optical fibers embedded in elastomer and wound around the central steel wire. Steel strands act as a strength member, and these are surrounded by a continuously welded copper cylinder, which is a water and hydrogen diffusion barrier. This also carries the power for the repeaters. An outer layer of low-density polyethylene provides cable insulation and abrasion resistance. |

Detail of cable and core construction

[Undersea Lightwave Communications p.234] |

Section of 1982 SL cable prepared in November 2021 |

The SL Sea Trial (September 1982):

[Undersea Lightwave Communications p.65]

The sequence of operations at the test site were:

Survey of sea trial site;

Lay tail cable with splice box, repeater, and 10.4 km of active cable;

Hold in this configuration for 18 h;

Recover 10.4 km of cable;

Lay 17.5 km of active cable;

Hold in this configuration for 2 h; and

Recover active cable, repeater, and tail cable.

Technical details of the test connections |

The Results of the Tests:

18-km cable and repeater performed as expected during laying, holding, and recovery operations in 5.5-km deep water.

Error-free transmission of 274 Mbit/s and 420 Mbit/s was demonstrated during 1-h test periods in all phases of operations.

Maximum loss change due to temperature, tension, and pressure was less than 0.1 dB under all conditions.

The cable, repeater, and splice box were recovered in original working condition.

3000 FM [fathoms] Sea Trial 1982 - SL Lightguide Cable

North Atlantic Ocean 35° 10' N, 54° 10' W

|

Map showing the test location:

The deep-sea trial was followed by further development of the components of the system. In 1985 a 107km SL system, OPTICAN, was installed between Gran Canaria and Tenerife in the Canary Island chain. This installation served as a test vehicle for the use of SL technology in the upcoming TAT-8 transatlantic cable, which was proposed for 1988.

It was reported in February 1986 that “The most ambitious experiment was a cable AT&T laid last autumn, running 116 kilometres between Tenerife and Grand Canaria in the Canary Islands. After testing the system with two repeaters, engineers from the Bell Labs of AT&T intentionally broke the cable and successfully spliced in a third repeater, demonstrating that they could recover and repair TAT-8 if necessary.”

[New Scientist Feb 6, 1986]

According to TE Subcom, the successor to Simplex, OPTICAN was ready for service in 1986. The cable provided four 140Mb/s circuits and remained in service until 2000.

When TAT-8 was laid in 1988 using the SL technology, it became the first optical fiber cable to span the Atlantic. TAT-8 was a joint project of AT&T, BT, and France Telecom; the cable was made by STC and Alcatel and laid using CS Long Lines, CS Alert (4), and CS Vercors.

The Holmdel Ocean Simulation Facility

In 1971, Bell Labs built its first hydrostatic test chamber at the company's Whippany, New Jersey facility. According to an article in the Bell Laboratories Record, March 1971:

At the bottom of the ocean, communication equipment is subjected to some of the most extreme environmental conditions any electronic gear will encounter. Engineers must be certain that their equipment will withstand the stresses and pressures of these depths and will operate reliably for long periods of time, since repair and maintenance is very costly. That's why Bell Laboratories has built a hydrostatic test chamber at Whippany, New Jersey, for determining the behavior of equipment in simulated ocean environments with conditions equal to or greater than those found on the ocean floor.

[Simulating the Ocean Environment. Joseph M. Jacisin and Robert R. Andres]

The pressure vessel was built of high-strength steel, and weighed 60,000 pounds. It could simulate an ocean depth of 36,000 feet for testing cables and equipment. Other than this article, I have not found any further information on this facility, and it's not clear why another ocean simulation facility was built at Holmdel about eight years later.

This 1979 press release, courtesy of the Nokia Bell Labs Archives, was published in the Bell Laboratories Record, August 1979.

Undersea lightguide cable tested in Bell Labs “artificial ocean”

An experimental glass fiber cable is being tested for possible undersea use in a simulated ocean environment below the grassy lawn of the Bell Laboratories facility in Holmdel, N.J.

The new glass fiber cable is only one-half the size but can potentially carry at least twice as many circuits as the latest coaxial cable now in undersea use, according to Robert Gleason, supervisor of the Bell Labs undersea cable design group.

Using ultra-transparent hair-thin glass fibers for undersea cables offers other advantages in addition to size reduction and increased information handling capacity, Gleason pointed out. “Because much more of the smaller cable can be coiled in a cable ship’s hold, only one reloading would be needed for an entire transatlantic installation-compared to five reloadings needed for coaxial cable.”

Last year, after more than 10 million calls and 22 years of uninterrupted service, the Bell System retired its first transatlantic cable, TAT-1, that could handle 48 circuits. The Bell System’s new TAT-6 transatlantic cable with a 4200 circuit capability costs the same to operate and provides over 80 times the traffic capacity. The new experimental lightguide cable will be capable of providing over 8000 circuits in its present form and can be expanded to carry much more traffic as the lightguide technology evolves.

Gleason said that much is already known about ocean cabling at Bell Labs because of the Bell System’s long history of developing and installing undersea cable, but studies must be done on how the lightguide cable would withstand ocean pressure, temperature, tension, handling and aging effects.

The “artificial ocean” was designed by Bell Labs to permit its engineers and scientists to subject the experimental lightguide cables to all of these conditions. Sophisticated control equipment will simulate most undersea conditions that can be expected, with ocean temperatures ranging from 3° to 30°C., and pressures to 10,000 pounds per square inch (simulating a depth of over four miles).

Gleason called the ocean “a friendly environment” once the cable is in place on the ocean floor. Pressure and temperature are fairly constant; marine animals ignore the unpalatable polyethylene cable; and, except for possible damage incurred along the continental shelves from ships’ anchors and fishing trawler gear, “the cable more or less just lies there.”

“But,” he added, “cable laying and recovery procedures have always imposed severe engineering constraints on cable designers. These apply to the lightguide cable as well.”

The experimental cable has a stabilizing inner steel wire, surrounded by a core made up of twelve hair-thin glass fibers in protective wrapping. Around the core is a spiral strand of steel wires, giving the cable strength and weight. A metallic conductor surrounding the strand serves as both a power conductor for cable repeaters and a waterproof barrier for the glass fibers inside. Sheathing the conductor is a thick polyethylene layer for high voltage insulation, covered with a polyethylene jacket.

The new lightguide cable was designed by Bell Labs and is being developed jointly with Simplex Wire & Cable Company of Portsmouth, N.H. The glass fibers in the experimental cable were fabricated by Bell Labs from glass preforms provided by Western Electric.

“Use of undersea lightguide cable is several years off,” Gleason said. “Testing of the experimental cable began in May and every aspect of the cable’s performance has to undergo careful, extended study.”

“When a new cable system is submerged two or three miles down across nearly 4000 miles of water, it’s got to be reliable. You’ve got to be right the first time,” he said. |

In his 1999 book on fiber optics, “City of Light,” Jeff Hecht notes that “Tests of 100-meter samples began in September 1979 in an artificial ocean Bell Labs had built at Holmdel to test the coaxial cables for TAT-6. Elaborate instruments controlled temperature, pressure, and cable tension. The results looked good.”

Holmdel, New Jersey, was for 44 years (1962 until 2006) the main development facility for first the Bell System and then Bell Laboratories. In 2013 the property was purchased by Somerset Development Corp, which now operates the site under the name of Bell Works, preserving the integrity of the Eero Saarinen building and maintaining an interest in the history of the site.

In 1984, Jeremy Bernstein, at that time science writer for the New Yorker, and himself a noted theoretical physicist and lecturer, published “Three Degrees Above Zero: Bell Labs in the Information Age.” In this book the author describes many of the important discoveries and inventions made at the Laboratories, interspersed with short biographies and interviews with key researchers working on then-current projects.

The “Telephone” section of the book concludes with what we now know to have been the major technology of the era – fiber-optic subsea cables – which revolutionized the telecommunications industry and led to today’s world-spanning network of hundreds of thousands of miles of cable.

In 1983, while visiting various Bell Labs facilities as part of his research for the book, Dr. Bernstein interviewed David Thomas at Holmdel. Thomas was at that time executive director in charge of transmissions and responsible for supervising the development of fiber-optics systems, including the SL Lightwave project. He and his associate Jack Stauffer showed Bernstein the 18km of recovered cable from the SL sea trials and gave him a tour of the Ocean Simulation Facility, both of which Bernstein subsequently wrote about in his book (see below).

I contacted Dr. Bernstein in January 2022 while I was working on expanding and updating this page of the Atlantic Cable website, and he very kindly gave me permission to reproduce these extracts from his book to fill in some of the background of the SL Lightwave cable project and the Ocean Simulation Facility:

Three Degrees Above Zero: Bell Labs in the Information Age

Just as Murray Hill specializes in research, the 8 percent or so of the activity for which the Labs is probably best known, Holmdel specializes mainly in development. One of the most significant areas deals with transmission, which includes the field of fiber-optics transmission. I was fortunate to learn about this activity from David G. Thomas, the British-born chemist who has been, since 1976, executive director of the Transmission Systems Division.

. . .

In his present activity, Thomas has a staff of about 550 and an annual budget of approximately $87 million. He is concerned with transmission-related activities that range from communications satellites to underwater fiber-optics cables.

. . .

Thomas is also responsible for the development of many of the terrestrial fiber-optics telephone systems and the proposed transatlantic cable. On 16 November 1983 AT&T was awarded a $250-million contract to design and develop a major portion of it, in a competition decided by the postal, telephone, and telegraph authorities of the Atlantic basin countries. In September 1982, Thomas’ group laid and retrieved a section of submarine cable with a repeater, at a depth of 18,000 feet, a thousand miles off Cape Hatteras. As Thomas explained, the fact that it was laid successfully at such an enormous depth, a record for fiber-optics submarine cables, was very important. As he remarked, "Sometimes you have to pull the cable back up--without breaking the fibers."

. . .

One of the things that Thomas wanted me to see at Holmdel was the “artificial ocean.” Housed in a long chamber near the main laboratory building, the “ocean” is filled with saltwater kept at deep-sea temperature and pressure. Fiber cables in it are maintained under those conditions to see how they bear up. Joining us for this visit was Jack Stauffer, head of the Lightwave System Development Department, that wing of Thomas’ operation that has to do with fiber-optics communication.

. . .

Stauffer worked on conventional undersea-transmission systems before switching to the fiber system in 1979.

“I was looking at fiber-optics transmission from a developer’s point of view,” he explained. “We had heard a lot about it from the research area. The appropriate lasers had been demonstrated about seven years earlier. But was fiber communication really more economical than pursuing another generation of the old cables? What would the fibers really cost?”

. . .

Stauffer was speaking while he, and I, and David Thomas were on a tour of the laboratories that Stauffer oversees. One of them had the latest fiber-optics, central-office-circuit apparatus—an entire wall of electronic equipment. One could see the exact place on the fiber where the beam of light stopped and was converted back into electric current. The fiber cable came into the board and the light was converted into a current of electricity, which can run a telephone.

We then went into a lab where the cable that had been lowered 18,000 feet into the ocean is now stored in a tank under the floor. Then we went to the artificial ocean where a similar cable was under high pressure. If all goes according to plan, in 1988 one will be able to call Europe over a cable just like this one [TAT-8]. Its immediate predecessor, a classical copper cable of a design first installed in 1976, went under the ocean in July 1983. It can handle 10,000 simultaneous transatlantic calls, a stunning improvement over the first copper transatlantic voice cable—the 1956 version—which could handle only fifty-one calls. The 1988 fiber cable will be the eighth transatlantic cable. It will transmit 560 million bits of information per second, which translates into 40,000 simultaneous telephone calls. |

In November 2021, 38 years after Jeremy Bernstein’s visit to Holmdel, I was able to examine that same length of SL cable, still stored in the main building, and tour the Ocean Simulation Facility, Building 10 on the Holmdel site. This building, long disused, is now in disrepair, but still houses the main control panel and the pumping machinery.

The invitation to Holmdel came from a Bell Works executive who was interested in the history of the 18km of cable stored in the basement. During my visit we cut off a number of short sections of the cable, and I later prepared this display piece from one of them:

For reference, here is the cable and core construction diagram shown earlier |

|

These photographs show the Ocean Simulation Facility in November 2021:

Building 10

Ocean Simulation Facility

|

Main control panel |

Panoramic view of machinery room |

References:

Bernstein, Jeremy: Three Degrees Above Zero: Bell Labs in the Information Age, New York, 1984, Charles Scribner’s Sons

.

Hecht, Jeff: City of Light, New York, Oxford, 1999 Oxford University Press.

Runge, Peter K. and Patrick R. Trischitta: Undersea Lightwave Communications, New York, 1986, IEEE Press.

Shimura, S., Editor: International Submarine Cable Systems, Tokyo, 1984, KDD Engineering and Consulting, Inc.

|